CDB Application Increases Safety of Flight

Excessive vibration has caused catastrophic component failure resulting in destruction of aircraft and loss of life.

Drivetrain components are a critical safety system for rotary winged

aircraft. Excessive vibration has caused catastrophic component failure

resulting in destruction of aircraft and loss of life. Helicopter operators

recorded data detailing vibration related issues concerning the aircraft; this

information includes Precautionary Landings, Forced Landings, accidents and

incidents related to excessive drivetrain vibrations. CDB will mitigate these

types of risks and hazards while increasing crew confidence in the machine.

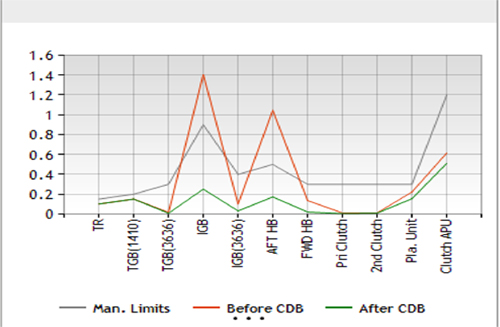

CDB is a “Preventive Maintenance Process” it keeps the vibration deterioration

rate low and moves component lifetime closer to TBO in order to eliminate potential risks of catastrophic component failure.

potential risks of catastrophic component failure.

By reducing vibration in the drivetrain, and keeping it low through preventive

maintenance, the aircraft can achieve and maintain a minimum vibration profile

over its life, therefore increase aircraft safety.

CDB application is a very useful tool for identifying and troubleshooting

various material issues beyond the drivetrain. This can result in important

material deficiencies being identified and resolved prior to a casualty.

See CDB results samples »